In this section you can navigate through our products and quote those that are your interest |

Products

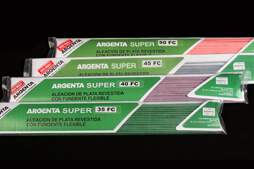

BRAZING

|

||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Low Fuming Brass RodsSOLDARGEN ST ( Low - Fuming Brass )Brazing alloy for Brass, Bronze, and ferrous materials. International Standard

Technical Features

Chemical Analysis (%)

Special Features SOLDARGEN ST brazing alloy is specially formulated to resist high mechanical demands. It contains Manganese for greater resistance, Silicon as deoxidant agent, and Tin for greater resistance against rust. It has the best fluidity level of its kind. It produces highly mechanically resistant joints of perfect chemical stability against corrosive agents. Very low fuming level during process. Easy to use. It produces clean and poreless finishing. Deposits get the base metal tint in brass and bronze. Applications Cast Iron, Soft Steel, Copper and its alloys, and Nickel brazing. Locksmith part joining. Car body manufacture and repair. Zinc plated pipes and boards. Vehicle and steel furniture manufacture and repair. Hydraulic machinery manufacture and repair. Brazing instructions Clean the zones involved. Apply enough amounts of ARGENTA FLUX 200 ROSA powder or paste. Using the torch, heat up the parts to be brazed evenly. Apply the alloy once the flux takes a liquid appearance. Spread over using the neutral or minimally reducing flame of the torch. Appearance Ø 2,4 mm. - Ø 3,1 mm. - Ø 4,0 mm. - Ø 5,0 mm. - Ø 6,0 mm. x 1000 m rods. |

|||||||||||||||||||||