In this section you can navigate through our products and quote those that are your interest |

Products

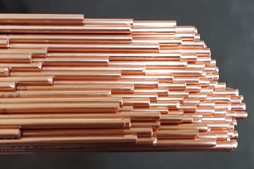

Welding

|

||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brassn ElectrodesARGENTA 812Exclusive aluminum brass electrode, highly alloyed for the manufacturing and reloading of parts under strong corrosion and cavitation.

Mechanical Features

Main Features 1) Deposits are extraordinarily resistant to corrosion, cavitation, erosion, and metal - metal wearing, mainly in the presence of sea water. Aplications ARGENTA 812 has been specially formulated for aluminum brass welding of the Cu-Al, Cu-Al-Mn, Cu-Al-Ni alloy family and similar. Typical examples are welding and reloading of shipping propellers and shaft propellers, Welding and building of turbine engines. For reloading of carbon steel parts, weakly alloyed and stainless steels, Cu alloys. Restoring of coupling bearings for laminating rolls. Well recommended for the reparation of body pumps under wearing caused by turbulent and saline fluids (cavitation). Welding positions  |

|||||||||||||||||||||||||||||||||||||||||||||